Kelin implements the strictest odor control standards and the quality of the panel is improved again!

publisherJIN

time2019/08/01

- The quality of the panel is improved again! Let you know more details of the operation and use the Kelin products confidently.

Kelin implements the strictest odor control standards and the quality of the panel is improved again!

In order to further comprehensively improve the quality and market competitiveness of Kelin chipboard products, tackle industry problems and comprehensively control the smell of sheet metal. Recently, Kelin do in-depth discussion and communication with core customers such as Sofia, Oppein, Weishang and Hongwei Wood, Huazhou Wood, Fenglin Wood and other brother factory between leaders and technicians.

Picture: The leader of Sofia came to Kelin to guide the work.

After several months of experimental verification and careful communication and discussion, many particleboard factories using miscellaneous wood as raw materials have agreed that the factors affecting the odor of custom-made wood-based panels include raw materials, types, structures, chemical materials used, and sheet health. The smell of the board is related to the raw materials. The smell of various woods is different. For example, eucalyptus and camphor wood have special odor. The raw materials are mildewed and rot can cause odor, and the smell of fresh wood is large. The permeability of the sheet and the way of health affect the artificial board. The odor is emitted; some paraffin waxes used in the production of wood-based panels have low purity, contain impurities and odors, and release irritating odors; the artificial plate hot pressing process is not suitable, and the excessive temperature will increase the odor of the plates. In combination with the actual situation, Kelin introduced the most stringent internal control standards for odor control at the beginning of this month, and the product quality and comprehensive competitiveness have been further improved.

The smell of the board mainly comes from the raw materials of wood and the chemical raw materials such as paraffin. Therefore, the acquisition, storage, use of wood raw materials and the rational use of chemical raw materials, coupled with reasonable health and stacking is the key to odor control!

1. Wood raw material control

Kelin wood raw material composition and odor analysis

The core of odor control is to grasp the source. It is necessary to control the odorous tree species and the procurement, storage and use of rotten and moldy wood. For the trees in Anqing and surrounding areas, the wood raw materials purchased by Kelin are rich in softness in the southern foot of Dabie Mountain. Miscellaneous and hardwood resources, including soft, pine, willow, fruit, cedar, bay, tree, landscape, eucalyptus, etc., accounting for 45%; hardwood mainly contains: chestnut, Tree species such as sandalwood, eucalyptus, mulberry, oil tree and maple are 55% in total.

In order to analyze the odor level of each raw material in detail, Kelin tested and analyzed the odor level of more than 30 kinds of raw materials in the yard. Kelin saw more than 30 kinds of miscellaneous logs into pieces of the same size and size, according to industry standards. The odor detection method is used to detect the odor of all kinds of raw wood, and put all kinds of raw materials sealed by odor detection in the conference room for customer detection and identification! In the end, Kelin analyzed the odor of eucalyptus and skunk over 3 grades, and set it as the early warning and reject grade raw materials. The odor grades of other wood raw materials were all lower than 2.8, which was a usable wood raw material.

Picture: Kelin conference room raw materials sample

Kelin wood raw material acquisition, stacking, health and use regulations

For the raw materials containing skunk, our company has resolutely refused to accept. For the raw materials containing eucalyptus, we have finely controlled the proportion of purchases. For more than a certain proportion of eucalyptus raw materials, we will make certain deductions for the suppliers of logs, and draw The designated area is used for stacking eucalyptus, and the raw material that does not contain eucalyptus is stacked in the designated large yard area, and the raw materials with more than 2% of eucalyptus are stacked in the designated small yard area. For raw materials with more than 2% coffin, it is necessary to sort the first time, pick out the coffins and stack them, and other raw materials are stacked in the large yard.

Kelin has formulated different health regimes for the raw material diameter of the incoming materials for 1-2 months. Currently, the incoming materials are generally mixed logs of more than 10cm in diameter. For a small number of logs with diameter less than 10cm, the health period is 30. Left and right, the health of the thicker raw materials is extended to 45-60 days. According to the date of incoming materials, the detailed recording time period of the sub-area is piled up and used. After the wood of one piece is used, the sweeping machine will clean the wood chips, sandstone, bark and other impurities on the super-thick surface and then re-stack the new wood. Raw materials.

For the raw materials of large and small yards, according to different production orders, the yard timber is used reasonably. The raw materials of the large yard are mainly used for the production of customers with special requirements for odor. For small yards, raw materials containing a small amount of eucalyptus are used for production. Orders such as eucalyptus addition, non-closed cabinets, and outdoor office furniture are required. When the raw materials of the large yard are not sufficient, the wood containing the eucalyptus in the small yard is manually sorted, and the eucalyptus logs are separately piled up, and other raw materials are used to supplement the materials of the large yard. In addition, when mold or decay is found during feeding, it is selected in time and used as an energy center for wood fuel.

Picture: Workers are working on strict eucalyptus sorting &

Launch all staff to control the smell

Each section of the security department (12H class) arranges a supervisor to conduct a daily inspection of the wood area of the eucalyptus tree, requiring a patrol cycle every 2 hours. If the eucalyptus odor is found in the eucalyptus-free area and a small amount of eucalyptus exists, it needs to call in time. After the inspection and acceptance personnel arrive at the scene to verify, after verification, the signature is confirmed, deducting the resource security department and the inspection quality inspector 500 yuan / time, and rewarding the inspection personnel 50 yuan / time.

The chairman of the board of directors, the executive vice president, the production and operation department, the staff of the preparation section, the craftsman, the deputy duty officer of each class, and the sales department personnel must conduct daily inspections on the raw material yard, no less than 3 times a day, and find that the no-wood area is still There are coffins and odors, and each reward is 50 yuan.

2. Chemical raw material control

Fully refined paraffin

The chemical raw materials of chipboard mainly include formaldehyde, urea, melamine and paraffin. Among them, formaldehyde is colorless and odorless. Both urea and melamine are white crystals. The purity is high and there is no odor. It can bring odor to wood-based panels. It is paraffin.

The main role of paraffin in our country is to produce candles. The melting point is mainly due to the season of adaptation. The high melting point is suitable for the season with high temperature, and the low melting point is suitable for the season with low temperature. The main difference between fully refined paraffin and semi-refined paraffin is the amount of oil. The oil content of fully refined paraffin is less than 0.8%, the purity is high, the impurities are less, and there is no odor. The semi-refined paraffin has less than 2.0% oil content and more impurities. An odor may occur after pressing. Domestic candle factories mainly use semi-refined paraffin as raw materials. The use of paraffin in artificial board enterprises is mainly to lubricate equipment and increase the waterproof performance of wood-based panels. Domestically exported to the international market and some high-end wood-based panels companies use fully refined paraffin wax.

Kelin chipboard is made of fully refined paraffin, light color, free of impurities and good waterproof performance, no odor!

Picture: kelin uses fully refined paraffin

3. Improve packaging, strengthen health

In order to strengthen the health and balance of the plate after hot pressing, Kelin insisted on sanding after 48 hours of minimum heat preservation (special requirements can be extended), sanding the plate, in order to enhance the breathability and odor of the plate, and After careful communication, the quality of Sofia is now packaged in a bag-type package. After sanding, the plates stacked in the finished warehouse can be continuously maintained and odor-exposed. After sufficient ventilation, the odor can be fully improved.

Picture: Kelin's finished warehouse Sofia area and Sofia leadership to communicate the best packaged breathable regimen &

4. Scientific guidance, enhanced display

At present, the consumers of the terminal have a big misunderstanding. First, they think that the particle board and the particle board are made of garbage materials and scraps. They are naturally odorous and prone to mold and rot. Second, they are considered to be irritating (including irritating) in cabinets and wardrobes. The smell and the smell of the logs themselves are all released by formaldehyde. On the one hand, the sales of ordinary custom home stores are unprofessional, misleading marketing, and on the other hand, the consumer's herd mentality, the odor problem is magnified.

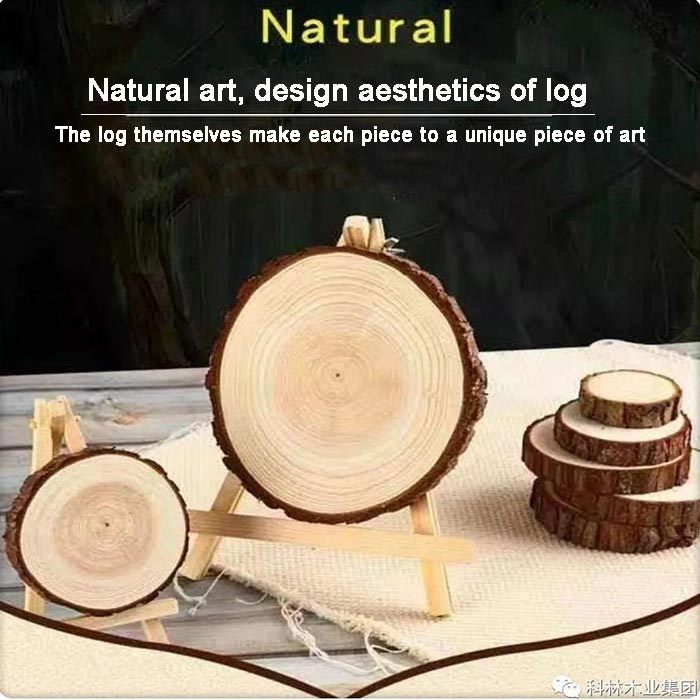

In order to help downstream customers solve this problem, Colin Brand Management Center divides and logs the logs into uniform size bottling and dicing bracket display, and merges our promotional videos with downstream customer videos to serve as props at the terminal. The store display has increased the selling point of household products, eliminating the doubts that consumers have always thought that particleboard is the production of scraps and scraps, allowing consumers to get close contact with the home substrate in the terminal store, identify the smell of logs, and fully experience The charm of the log satisfies the "solid wood complex" of the consumer, solves the problem of smell, and quickly realizes the deal! Let consumers pay attention to this kind of household products, which are carefully selected for the home substrate logs, remove the odor, rotten wood, and use the large-diameter quality logs to produce the household products.

Picture: Kelin pure board raw material sample display

After several months of odor control and verification, the current odor control level of Kelin Pure Board has been comprehensively improved, laying a solid foundation for the improvement of its quality and brand awareness. I believe that Kelin will keep its initial focus and continue to strengthen its quality. Control and upgrade, produce more safe, environmentally friendly, high-quality, fully functional sheet products to meet the needs of different customer groups!